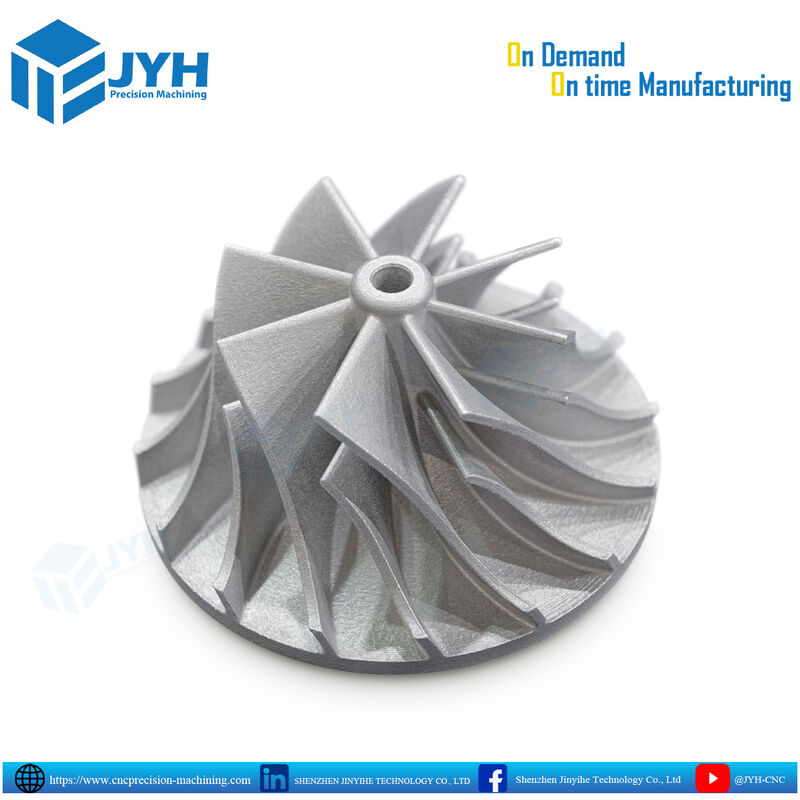

The CNC Machined Aluminum Turbo Impeller (Compressor Wheel) is a high-performance rotating component engineered for turbochargers, air compressors, and high-speed fluid systems. Manufactured using advanced multi-axis CNC machining, this impeller delivers exceptional aerodynamic efficiency, dimensional accuracy, and surface integrity—making it suitable for demanding automotive, aerospace, UAV, and industrial applications.

At JYH Precision Machining, each impeller is produced from premium aluminum alloy using 5-axis CNC technology to achieve complex blade geometry, tight tolerances, and superior balance performance. Compared with conventional cast impellers, our CNC-machined impellers offer significantly higher strength, consistency, and fatigue resistance.

This product is ideal for customers seeking lightweight, high-RPM, and high-efficiency compressor solutions with full customization support.

Key Features

- ✅ 5-Axis CNC Machined from Solid Aluminum Billet

- ✅ Optimized Blade Geometry for Maximum Airflow Efficiency

- ✅ High Dimensional Accuracy (up to ±0.01 mm)

- ✅ Excellent Surface Finish on Blade Profiles

- ✅ Superior Mechanical Strength vs Cast Alternatives

- ✅ Custom Sizes, Hub Bores & Blade Designs Available

- ✅ Dynamic Balancing Support for High-Speed Applications

- ✅ Prototype to Mass Production Capability

Typical Applications

- Turbocharger compressor wheels

- Automotive performance turbo systems

- UAV propulsion and air management systems

- Industrial centrifugal compressors

- High-speed air blowers

- Experimental and motorsport turbo assemblies

Material Options

Standard material:

- Aluminum Alloy (6061 / 7075 / Custom grades)

Optional materials on request:

- Magnesium alloys (AM60B, AZ91D)

- Titanium alloys

- Stainless steel

Surface treatments (optional):

- Anodizing

- Shot blasting

- Polishing

- Cerakote coating

- PEO / micro-arc oxidation

Manufacturing Process

- Raw aluminum billet preparation

- 5-axis CNC rough machining

- Precision blade profiling

- Hub bore machining

- Fine finishing of aerodynamic surfaces

- Deburring & edge conditioning

- Dimensional inspection (CMM / gauges)

- Optional dynamic balancing

- Final QC and custom packaging

Every part undergoes strict quality inspection to ensure repeatability and performance consistency.

Technical Capabilities

|

Parameter

|

Capability

|

|

Machining Method

|

5-Axis CNC Precision Machining

|

|

Dimensional Tolerance

|

Up to ±0.01 mm

|

|

Surface Roughness

|

Ra 0.8–1.6 μm (customizable)

|

|

Maximum Diameter

|

Custom (typ. up to 300 mm)

|

|

Minimum Feature Size

|

≥0.2 mm

|

|

Concentricity

|

≤0.01 mm

|

|

Production Volume

|

Prototype to Mass Production

|

|

Lead Time

|

5–15 working days (depends on complexity & qty)

|

CNC Machined vs Cast Impellers — Technical Comparison

|

Feature

|

CNC Machined Impeller (JYH)

|

Cast Impeller

|

|

Material Structure

|

Solid billet, uniform grain

|

Porous, inconsistent

|

|

Dimensional Accuracy

|

Very high (±0.01 mm)

|

Moderate

|

|

Blade Precision

|

Excellent

|

Limited

|

|

Mechanical Strength

|

High

|

Medium

|

|

Balance Stability

|

Superior

|

Lower

|

|

Fatigue Resistance

|

Excellent

|

Average

|

|

Custom Geometry

|

Fully customizable

|

Limited

|

|

Suitable for High RPM

|

Yes

|

Restricted

|

Conclusion: CNC-machined impellers provide higher reliability, efficiency, and lifespan—especially critical for high-speed turbo applications.

Why Choose JYH Precision Machining?

With extensive experience in aerospace-grade CNC machining and complex rotating parts, JYH offers:

- In-house engineering support

- DFM optimization before production

- Stable batch consistency

- Flexible low-volume and mass production

- Strong QC system (CMM + manual inspection)

- Export-ready packaging

- Fast response for RFQs and design changes

From prototype validation to production ramp-up, we support your project at every stage.

Customization Services

We support full customization based on your drawings or samples:

- Outer diameter & hub bore

- Blade count & angle

- Backface geometry

- Weight optimization

- Material selection

- Surface treatment

- Logo marking or serial numbers

Just provide STEP/IGES files or 2D drawings.

Quality Assurance

Each impeller can be supplied with:

- Dimensional inspection report

- Material certificate

- Surface treatment report

- Dynamic balancing report (optional)

Our QC process ensures every unit meets your mechanical and dimensional requirements.

Packaging & Delivery

· Individual protective packaging to avoid blade damage

· Foam or custom trays for bulk orders

· Export cartons or wooden cases available

· Global shipping support via DHL / FedEx / UPS / sea freight

Request a Quote

Send us your drawings or specifications to receive a fast quotation.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!